By Ilka Gansera-Lévêque

•

August 12, 2018

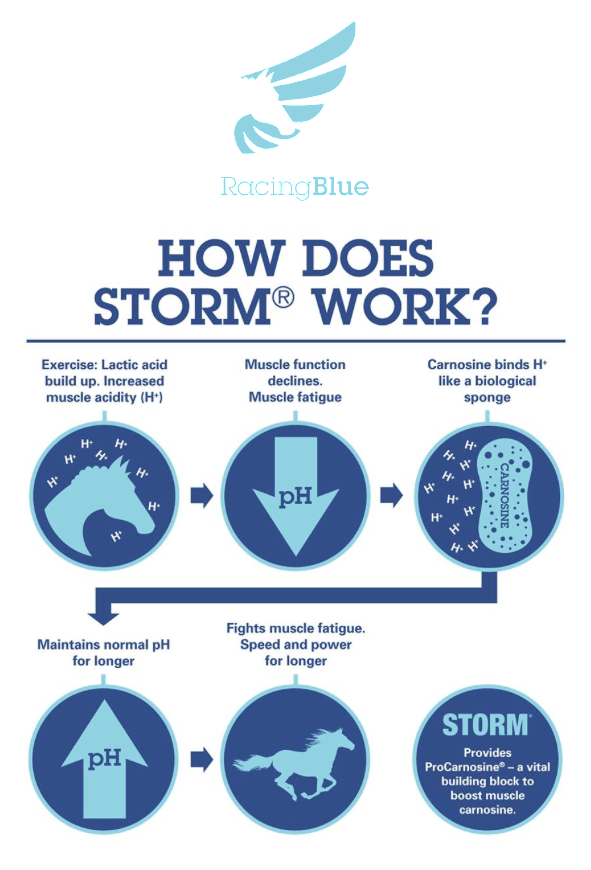

Guest post by: Dr. Cath Dunnett of Independent Equine Nutrition (IEN). There are intrinsic contamination risks associated with horse feed and supplements which have in recent years been responsible for a series of post-race positives. Contamination of feed principally occurs due to the accidental introduction of an ingredient containing a naturally occurring prohibited substance. There are many stages in feed production and accidental contamination could happen at several stages, for example, contamination with weeds containing prohibited substances during the growth of cereal or other ingredients. Inadvertent contamination could also occur during harvest through the sharing of equipment or storage, or during cross-contamination during shipping or transport to the mill. There is potentially an increased risk of such contamination as a larger number of ingredients are sourced from across the globe and feed and supplement production becomes a worldwide operation. Naturally Active Compounds The feed industry takes the risk of contamination incredibly seriously and strategies have been implemented to reduce contamination risks from ingredients both produced at home and imported. Broadly the feed industry has a very good knowledge where the risks for contamination with prohibited substances lie, however, these can be complicated when additives such as herbs, spices, or plant extracts are used in feed or supplements. Here there are two key considerations – firstly, many plants naturally contain pharmacologically active compounds that could be considered as prohibited substances. Secondly, the country of origin may lack sufficiently thorough quality control systems. The post-race positives due to morphine contamination of feed were reportedly due to poppy seed contamination of one or more ingredients. It may be a surprise to many that morphine-containing poppies had until recently been harvested in various locations around the UK, under a specific license and strict control and management, for the production of pharmaceuticals. A greater amount of morphine is found within the poppy seed head, whereas the seeds themselves contain only a very low level of morphine. It’s worth mentioning that the commonly seen red field poppies do not present a notable contamination risk, as they contain very low levels of morphine, if any at all. Interestingly, in human food production, fragments of poppy seeds and heads do infiltrate the food chain. Yet, the European Food Standards Agency (EFSA) does not list morphine as an undesirable substance and there remains no minimum legal limit for morphine in human food. Significant Physiological Levels In Racehorses Whilst the potential for low residual levels of morphine in the food chain may be physiologically inconsequential to humans, it remains extremely problematic to trainers. Morphine is a significant analgesic and therefore must be regulated in a way that prevents its potential for abuse. Investigations into contamination might successfully conclude that any post-race positive test was as a result of feed contamination, however, it remains the case, that the horse has raced with a level of the ‘drug’ in its system. Prohibited substance testing is incredibly accurate and a positive post-race result will be returned on minute levels. Whilst regulatory bodies over the world may choose to take a pragmatic view, nevertheless, there is no ‘official’ threshold for morphine in post-race samples in racehorses, therefore, a line must be drawn. For welfare reasons, there is no scientific evidence to allow us to determine an acceptable level where no physiological effect is confirmed. Scheme Accreditation The UK feed industry developed a quality assurance code as a risk management measure to reduce the risk of prohibited substances entering equine feed and to safeguard the interests of consumers and feed producers and suppliers. The aim of any such quality assurance scheme is to understand where the risks lie within each part of the supply chain and then how to mitigate those risks. Here are a few areas where such a scheme can assist: Ensuring a long-term relationship with suppliers. Using an appropriately accredited manufacturing facility. Ensuring that everyone involved in the supply and manufacturing chain, including, farmers, harvest contractors, processors, hauliers, storage suppliers, trainers and stable staff understand the importance and the risks posed by prohibited substances and the consequences of minute levels of contamination. Encouraging collaboration between different manufacturers, so that concerns regarding ingredients or products, can be shared following analysis. Ensuring that marketing claims regarding prohibited substances are factual and not misleading. Accredited companies are likely to be audited annually, to ensure their compliance with the scheme and that robust quality control systems remain in place to reduce the risk of contamination by prohibited substances. Gathering Information In addition to the efforts made by the equine feed industry, trainers themselves have a responsibility to understand the contamination risks and actively manage them. After all, it’s the trainer’s reputation and livelihood that is at stake. Trainers may receive some advice on this from their regulatory bodies and in the UK whilst attending the BHA trainer licensing course and any NTF seminars on the subject. So far as is possible, trainers must be totally aware of the constituent parts of everything that is fed to their horses. This information is readily available, as it’s a legal requirement for companies to provide such details on the packaging. Trainers would also be advised to enquire about the quality control systems that their manufacturer has in place to reduce the risk of contamination with prohibited substances. This could involve comprehensive risk assessments, raw material traceability and testing of both the ingredients and the finished product in some cases. Regardless of the size of the business, or their supply structure, all companies should have a robust system of traceability and quality control. For instance, my own company Racing Blue, follow a thorough quality control program in the manufacture of STORM ® Equus that includes every batch of each raw material and finished product being tested for a wide range of prohibited substances prior to release for sale. Where a trainer uses a product manufactured abroad, sufficient questions of the importer/marketer should be asked, to ensure their processes match those in the home country. For instance, certain substances that are allowable in agricultural feed production in other countries, may be regarded a prohibited under the Rules of Racing in the home country. Daily Management Procedures It’s advisable for trainers to implement additional feed procedures in the yard, such as maintaining a comprehensive list of feedstuffs given to individual horses. This proves extremely useful should a post-race sample return as positive. Further to this, keeping an accurate record of delivery dates, batch numbers and invoices, as well as retaining a copy of all associated delivery notes and other paperwork, provides further evidence, if needed, to establish the route of contamination. Better still, retaining samples of each batch of feed and supplement for about 3 months is an excellent process to implement, as this is the period of time over which a post-race positive is possible and the consequent regulatory process will last. Representative samples of feed (500g) and a supplement (100g) should be stored in a sealed plastic bag and labelled with the product name, batch code and purchase date. Should an investigation be necessary, the record keeping along with the feed samples will provide vital evidence. Feed or supplement manufacturers should also retain samples for re-examination if a problem arises, however, it’s a sensible precaution for trainers to do the same. Quality control processes and accreditation schemes have brought considerable benefit to the racing industry, however, historical positive cases with morphine and other substances demonstrate that accidental contamination can still happen, and there are always further improvements that can be made. Equally however, trainers have a pivotal role and must ensure they keep informed and up to date, so that they’re able to make the best possible feeding and feed management choices. You can find out more about feed analysis on the IEN website.